CREDIBLE DIVERSITY. BOUNDLESS APPLICATION OPTIONS

Our diversity is based, not least, on the close cooperation with our clients. This creative teamwork established various special materials that go beyond the provision of DIN standards. Our workshop within the R&D department will provide the support you need – anytime. Further technical information is available on request.

RAIL VEHICLES / RAILWAY TECHNOLOGY / PLANTS AND MACHINERY

Hi-form SSP 10 is a specially moulded thermoset laminate developed by the Erhard Hippe KG for the specific use as slide insert in Y25-bogies. It is particularly suitable for very heavy carriages and tank wagons because of the extremely high compressive strength, the elastic modulus and the sliding additives in the material. The bearing inserts have been successfully tested by the German rail companies. Hi-form SSP 10 has been in use for a six-year series since 1987. An authorization for the DB AG has been submitted.

Hi-cage 2000 is a thermoset material which has been developed by the Erhard Hippe KG for the application as ball bearing cages. It is distinguished by an excellent machinability, a very fine woven fabric, a very small number of lints, a high dimensional stability and a high compressive strength parallel and perpendicular to laminations. Hi-cage 2000 is offered in the requested diameters and wall thicknesses.

Hi-roller 2000 is a cotton fabric laminate which has been developed by the Erhard Hippe KG for the special use as support roller for stranding machines. It has an extremely high compressive strength and a high elastic modulus, which is the most important characteristic for the use as support roller. Combined with a very smooth surface it minimizes considerably the danger of burnouts of the support roller. Hi-roller 2000 is available in the size 1,050 x 1,020 mm up to 310 mm thickness (as one solid piece), as raw disk up to a diameter of 1,000 mm or as support roller ready for installation.

MECHANICAL AND ELECTRICAL ENGINEERING

This material for high temperatures was developed from a glass fabric and a modified epoxy resin. It has a particularly high compressive strength that allows a considerable contact pressure. In the form of boards, this asbestosfree material is used as THERMAL INSULATION in the parting zone of moulding and injection-moulding tools. Its thermal conductivity is extremely low, which has a positive effect on controlling thermal energy. We can supply Hi-therm WD as parallel-face, ground sheets or as finished parts according to your specification.

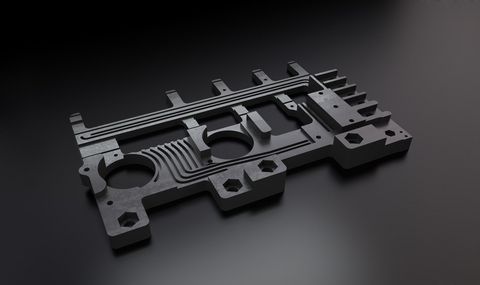

Hi-con 2000 is a thermoset construction material which has been developed by the Erhard Hippe KG for the machining of most complex structures. It is characterized by an excellent machinability, a high dimensional stability even at higher temperatures, a low water absorption and good electrical and dielectric properties. We offer Hi-con 2000 products as finished parts, machined according to your drawings.

[Translate to english:]

Spezifische Eigenschaften und Prüfwerte unserer Produkte finden Sie hier über unseren Produktfilter.